In manufacturing, viability hinges on production yield. In energy devices, viability hinges on conversion efficiency.

In manufacturing, viability hinges on production yield. In energy devices, viability hinges on conversion efficiency.

Less is less

The notion that higher conversion efficiency is better than lower efficiency is intuitive. With higher efficiency, more is produced from the same resource. Higher efficiency does have higher inherent value.

What is often counter-intuitive, however, is that low-price scenarios can produce dramatic economic impact from efficiency differences. As PV module prices drop, tolerance for lower efficiency solutions plummets.

In the PV Industry an oft-promoted premise is that “(Thin film panels) are not as efficient as crystalline cells, but generally cost less to produce.” Such promotional statements suggest a simple and consistent trade-off between efficiency and cost.

This is misleading.

The relationship of cost and efficiency is not consistent at different price levels. As part of an overall PV system, PV module efficiency impacts the comparative cost per watt of other system components.

The Catch-22 is that when PV modules drop in price, the lower performing alternative faces greater comparative price pressure than it did at higher prices. More for less (in terms of PV module pricing) forces even more from less (in terms of pressure to improve module efficiency).

Two reasons

In photovoltaics especially, there are two primary reasons for the compounding impact of efficiency on economic viability.

First, photovoltaic devices have relatively low energy conversion efficiencies. With low energy conversion efficiency, small absolute differences in efficiency can result in large proportionate differences. A one percent change in efficiency from 14 to 15% PV conversion efficiency, for example, represents a 7% value increase.

Second, in a PV system the primary energy conversion is done at the cell level within the PV module. PV modules require significant additional infrastructure and equipment to provide a complete PV generation system. As Ken Zweibel of the GW Solar Institute has explained, “Efficiency matters for reducing the impact of area-related and one-of-a-kind BOS costs and for reducing the cost of the module itself.”

In a PV installation, there is the PV module and there is ‘everything else’. That everything else is commonly referred to as Balance of System, or BOS. Such a simple label, however, underplays BOS sophistication and – more importantly for this discussion – its cost impact. The cost per watt for mounting hardware, electrical wiring, site preparation, site area and even inverters are all influenced by PV module efficiency.

PV modules currently represent about half of the initial system costs and the BOS the other half. As PV module prices drop, and modules become seemingly less important economically, the overall PV System costs actually becomes increasingly sensitive to module efficiency. This is due to the impact of efficiency and its cost per watt leverage on the BOS.

As Shyam Mehta of Greentech Media observed, “Conversion efficiencies affect both balance-of-system costs as well as viability in space-constrained markets.” Similarly, Zweibel’s insights included that at 2009 BOS cost levels, “a 5% (efficient) module costing nothing would have the same system price for residential rooftops as a 15% module costing about $1.50/Watt.”

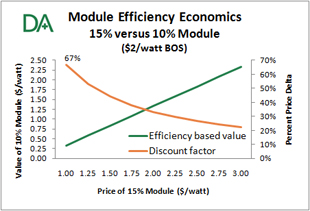

A similar relationship can be illustrated for the BOS influence by assessing the value of a 10% module at different 15% module price levels.

If the mounting hardware for the two modules is the same, for example, then the value of the 10% module must allow for the impact of the lower efficiency on the identical mounting cost. To reflect the value discount, the 10% module price should be lower on a cost per watt basis. Ironically, value-based price discounting can make it appear that the less efficient module is closer to grid parity as it will have a lower price per watt. This is not the case, of course, as the full system cost must be assessed.

As prices drop, lower efficiency modules require greater price discounting

As prices drop, lower efficiency PV modules require higher discounting

Different efficiency levels produce a non-linear influence of BOS costs on module value. In this example, when the 15% module is priced at $3 per watt, a comparable 10% module has a 22% lower value of $2.33 per watt. If the 15% module is priced at $1.50, the value of the 10% module is 44% lower. Should the 15% module drop to $0.67 per watt, a competing 10% efficient module has zero economic value. Below that price, the value of the 10% module would be negative and the customer would need to be compensated for the efficiency compromise.

Like BOS costs, maintenance costs are also affected by module efficiency, though they are not included in this illustration. To achieve a given output with lower efficiency, more modules with more module area are required. In terms of maintenance, this leads to more potential points of failure and more area to clean and maintain – all spread out over a larger area.

Implications

As observed in the post Sunset for SunFab, “competitive pressures from crystalline silicon” were cited by AMAT as a primary reason for discontinuing their thin film equipment product line. Nine percent efficiency amorphous silicon (a-Si) modules from AMAT’s SunFab were competing with multicrystalline modules reaching 15 percent efficiency and higher.

Lower prices in crystalline modules achieving higher efficiency put amorphous silicon alternatives between two jaws of an economic vise. While crystalline and a-Si technologies are not identical and do behave somewhat differently under differing conditions, the relationship of efficiency on PV economics is ever present. Improvements in crystalline efficiency and reduced prices have put intense price pressure on lower efficiency module alternatives.

Similar economic relationships can be observed between higher efficiency monocrystalline modules and multicrystalline modules. A drop in module pricing helps explain renewed momentum of high efficiency monocrystalline approaches.

Likewise, such economics of efficiency relationships applied to polysilicon quality during the recent PV industry polysilicon shortages. As polysilicon prices drove up cell and module costs, overall PV economics were less sensitive to polysilicon quality. At high polysilicon prices, cheap seemed not so bad – if it was cheap. With high quality polysilicon now cheaper, the converse is true. Polysilicon quality is more important at low prices and cheap polysilicon must now be good polysilicon.

9 Responses to “Economics of Efficiency in PV Systems”

Trackbacks/Pingbacks

- GUNTHER Portfolio twitter Weekly Updates #Solar #PV – 2010-08-14 | GUNTHER Portfolio - [...] @ddbits: Just Published at d-bits: Economics of Efficiency in #Solar #PV Systems https://d-bits.com/efficiency-economics/ via @AddToAny [...]

- Another PV Solar Polysilicon Crisis Looming? | d-bits - [...] their competitive position, as illustrated in The Economics of Efficiency in PV Systems, intense cost pressure on poly customers…

Hi David – this is perfect promotion material for guys that serve the high efficiency market. Also, could you share a bit on how you develop the efficiency vs cost model?

David, This is very nice analysis and I don’t disagree with the macro level of this dynamic or comparing extremes like a-Si with 15+% c-Si modules. If comparing peak watt ratings gave you precise information on relative kWh energy produced per day or year, I’d be 100% with you, but it doesn’t.

“Efficiency” in PV is of course AREA efficiency (W/m2)based on peak watts in (STC or PTC) fixed test conditions, inside on a flash tester. CdTe and modules using c-Si coupled with Prism’s holographic film do relatively better in low-light, diffuse light, & overcast conditions than standard c-Si modules. That skews the value to area efficiency relationship you present and makes the reality more subtle. Output degradation with increased temperature is also a big variable that would meaningfully change your results. If you are installing in high-light conditions in the desert heat, the difference between one c-Si module and another could be 0.3% loss per deg C vs. 0.25% for another and becomes significant at 50 deg C. In such conditions, we’ve observed Prism-design modules operating 10 deg. C cooler than other c-Si based modules, which could be a 3% output difference, overwhelming area efficiency differences. It’s too bad that the data set to translate your chart into the reality of installing in several distinct real-world sun/weather scenarios is kept within the big integrators knowledge base. Again, the artificial and not entirely reliable flash tested Wp metric is screwing up our ability to make more simple conclusions that will hold up to consistent use. As long as your readers understand that this is not the analysis end point for buying Module A vs. B, and is more you pointing out an important dynamic, I certainly applaud this work. Tom Kacandes, Prism Solar Technologies, Inc.

Hi Tom,

Thanks for outlining issues such as temperature differential.

As you note, it is likely easy to incorporate these into a model – if only those with the data would be more forthcoming.

I am intrigued by your Prism-design.

When preparing this article, I did some investigation into temperature gradients, spectral radiation, etc. High efficiency architectures like the Sanyo HIT need to be taken into account, as do the impact of trackers, parallel wired systems and MPPT capable inverters.

Anything which helps extract more harvestable energy (parallel, MPPT, tracking, etc.) will favor the higher efficiency solutions. Thus, it is never a level playing field.

In the case of lower efficiency module alternatives, it appears to always be a game of catch-up on a slope that only gets steeper.

The article is excellent. My comments are that there will also be price declines in some parts of the BOS cost such as the costs of inverters.

However, I do not see any price declines in the costs of maintenance for solar farms and those costs will soon become a more important factor that will favor higher efficiency modules.

Hi Alan,

Thanks. Excellent points.

A key contact at a large PV firm advised back in June that they were actively pursuing opportunities to lower maintenance costs.

The costs of maintenance will come down. New inverter capabilities and designs (e.g. microinverters, DC-DC converters) with parallel architecture, for example, allow per module monitoring. Parallel wiring diminishes the impact of soiling on harvested power.

With respect to the impact of module efficiency, lower module efficiency means more module area and more modules. More modules means more things that can go wrong. More area means more problems with soiling, etc.

Thus, if maintenance costs are reduced the higher efficiency module solution will still see a disproportionate benefit as compared with lower efficient modules.

It is all about getting more out of less.

Hi David, I just read your ”Economics of Efficiency in PV Systems” article and found it very interesting. I’m an Engineering Grad student from Stanford and am currently working on an innovation that would provide a significant boost in efficiency for thin film pv. It would be highly useful if I could understand in more depth the comparison you make between 10% and 15% efficiency cells, since our value proposition hinges on this type of argument. If it’s OK with you, please send me your e-mail address or phone number so I can ask you some specific questions. Thanks!

Mike

Hi Mike,

In a cost/watt relationship, module cost is inversely proportionate to efficiency. This is true for cost/watt or cost/kWh. As discussed in the blog post, the leverage of module efficiency is extended to the module cost and BOS cost.

Cost = module + BOS

Consider two efficiencies (Eff1 and Eff2) for two different modules (Mod1 and Mod2).

While there are many more variables involved, most of these apply to both of the systems being compared (e.g. DC:AC conversion rate, etc.). Thus, the formulas could be much more complex, but many terms would simply cancel out.

Solve for Mod2:

(Mod2+BOS)/Eff2 = (Mod1 + BOS)/Eff1

Eff1/Eff2= (Mod1 + BOS)/(Mod2 + BOS)

Mod2+BOS = (Mod1+BOS)*Eff2/Eff1

Mod2 = Eff2/Eff1*(Mod1 + BOS) – BOS

For the base case in the blog post ($2 module, $2 BOS – but with a 20% module):

Module Value Factor

10% – na

13% 0.60 30%

16% 1.20 60%

20% 2.00 100%

Because we are working with a 50:50 ratio (actual ratio in 2010 is 46% module, 54% BOS according to Susquehanna Financial Group), the numbers can be intuited rather than calculated. At 20%, the value of the 10% module should be 0, and it is. A 13% module should be worth 30% of the higher efficiency module, and it is. Etc.

‘Real-world’ system costs were $4.06/watt in November according to the Solarbuzz price index.

Rather than use a theoretical case as in the blog post, real-world comparisons between First Solar and Crystalline can be made. These are non-linear due to market aberrations, however, such as reputation and brand value, sales channel, local content, and bankability. German crystalline modules, for example, have long enjoyed a price premium in Germany.

Bankability can be modeled as ‘non’ bankable modules can be modeled with higher interest expense. An additional 1-2% financing premium over the 20 year life will provide a compounded difference of 8.75 to 18% to the cost/watt or cost/kWh. Greentech Media recently put a nice chart together comparing module costs with efficiency and bankability impacts incorporated.

In terms of performance under different environmental conditions (cold/hot, sunny/cloudy), as cited in some of the comments above, ultimately even if these are real the question is whether or not the market actually appreciates any benefit and whether customers are willing to pay any premium or not. We would need to see research on buying decision behavior, not claims of technical teams to properly evaluate this. Moreover, there are crystalline module designs (e.g. Day4Energy) and cell designs (e.g. Sanyo) that reduce shading impacts and enhance low light output. Devices that provide maximum power point tracking will also reduce the impacts of shading.

Aren’t you also neglecting that the BOS cost (per Wp) differs for CdTe vs. c-Si? You can’t simply hold BOS constant across the scenarios because CdTe requires different cabling, more labor, more land and more framing.

Hi Joe,

Exactly!

This is why the cost/watt is such a valuable tool for this type of comparison. In other words, this approach actually does take these items into account.

Virtually all of these things (racking, inverters, land, cable, labor) scale linearly with energy density = efficiency. Lower efficiency means more racking. More racking requires more labor and land prep. More strings means more inverters. More strings and more racking means more cabling, etc.

This impact of power density (efficiency) fundamentally creates the multiplier effect on the efficiency delta between the higher efficiency and lower efficiency choices. Same costs, spread over less output per acre/hectare.

In the above analysis the only major cost component not considered is the land cost.

In fact, the land value that should be considered is the value of the best alternate use. This is partly why higher efficient modules are favored for rooftops – more power from the same fixed area. The best alternative use to a lower efficiency installation is a higher efficiency installation and the greater power output.

Even if the lower efficiency product has slightly better performance in low light situations or different temperature conditions, ultimately the ability to make more kWh from the same area still tilts the scale in favor of the higher efficiency alternative.

Regards, David